Machined Components Manufacturing

Our state-of-the-art facility and expert team ensure precision engineering and high-quality products, meeting evolving client needs

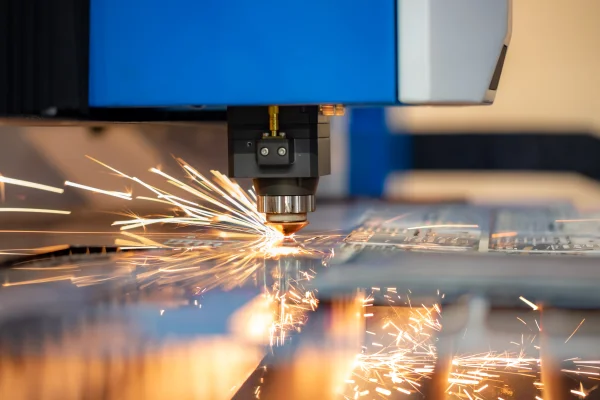

Laser Cutting

We have high precision laser cutting machine specialized in cutting industrial materials like stainless steel, GI sheet, Aluminum, Copper, CRCA, HR, and Brass in the various thickness to cut in desired design, excellent edge quality, consistency, accuracy and repeatability.

Press Brake

We offer precision sheet metal bending with CNC Hydraulic press brake AMADA from Japan. It leverages industry-leading bending technology and a variety of production-enhancing features that can be customized to resolve your specific challenges.

Welding

We handle all type of welding includes, MIG welding, TIG, SPOT and STUD welding. It allows high speed welding on thin sheets. The strong wire-feeder has a rugged design to withstand usage in challenging industrial environments.

Clinching

We offer clinching technique for point joining the sheet metals, used to alternative to spot welds, nut, screws etc. It is a simple process, fast, clean, inexpensive, environmentally friendly, and repeatable process. It is an effective solution for metal joining.

Spot welding

We have the fastest and cleanest Spot welding methods. Multiple metal sheets can be joined at the same time. No filler material is consumed. Its a low-cost process. Thinner metals can also be welded more efficiently.

Laser Marking

We have advanced laser engraving machine specifically for etching, marking, and engraving hard material with high speed, superior stability and low volume by automating the process through the use of computer software.

CNC Turning / DRO

We have advanced computer numerically controlled machines. They can have 2 axes, along with a multitude of machining capabilities, including threading, tapping, turning, facing, grooving, knurling with continuous operation.

Powder Coating

We have efficient curing and drying Powder coating processes. Its long-lasting and durable, hard finish. Powder coating is easy to maintain, no special solvents or cleaners are required. Its also resistant to corrosion and damage.

Contact Us

Here’s how you can contact us for any questions or concerns.